In the vast world of industrial components, there exists a silent hero that ensures the integrity of seals, prevents leaks, and safeguards the smooth operation of machinery—the humble crush washer.

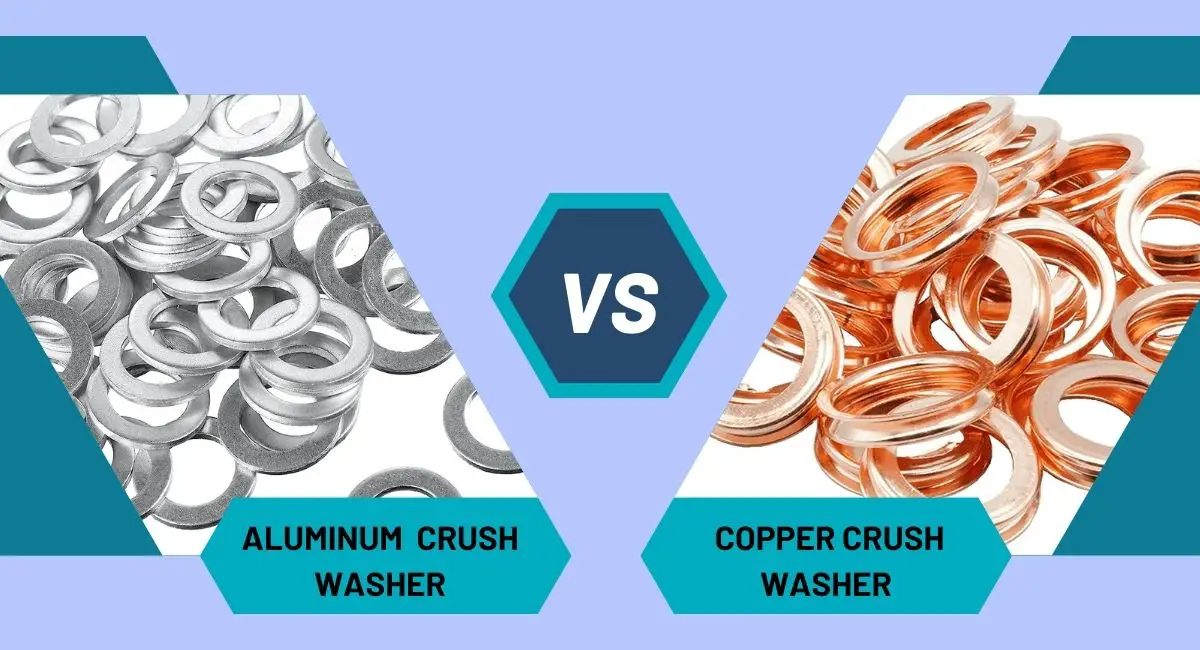

Often overlooked and underestimated, crush washers play a crucial role in maintaining the reliability of various systems, from automotive engines to hydraulic equipment and plumbing connections. And when it comes to crushing washers, the battle between aluminum and copper takes center stage.

And with the frustration of a leaking pipe or a faulty connection bringing your operations to a screeching halt, the right choice of crush washer material can make all the difference, providing you with a reliable seal and peace of mind.

In this article, we will focus on comparing two popular materials: aluminum and copper, understanding the qualities and limitations of each.

But before diving into the details, let’s start with the basics.

What is a Crush Washer?

A crush washer is a thin, flat ring typically made of a soft, malleable material. Its primary purpose is to create a tight seal between two surfaces, such as pipes or fittings, by compressing and deforming under pressure. The resulting deformation fills any irregularities or gaps, ensuring a reliable and leak-free connection. Crush washers find applications in a wide range of industries, including automotive, plumbing, hydraulic systems, and more.

Aluminum Crush Washers: Lightweight and Cost-Effective

Aluminum crush washers are small, flat rings crafted from aluminum, a lightweight and corrosion-resistant metal. When compressed under pressure, these washers’ design creates a tight seal between two surfaces. They are functional in various industries, including automotive, plumbing, and hydraulic systems. Aluminum, a popular choice for crush washers, offers several advantages and disadvantages.

Lightweight

For instance, its lightweight nature makes it ideal for applications where minimizing weight is crucial. Thanks to its remarkable resistance to wear and tear, the aluminum alloy emerges as an exceptional choice for crush washers. Its lightweight nature facilitates the installation process and enhances overall ease of use. With aluminum crush washers, you can rest assured that you’re utilizing a material that combines durability and convenience in a single package.

Low Cost

Aluminum crush washers present an affordable option due to the material’s cost-effectiveness. Not only are they economically viable initially, but they also offer exceptional durability, reducing the need for frequent replacements. This long-lasting quality of aluminum crush washers enhances their overall cost-effectiveness, providing a practical and economical solution for various applications in the long run.

Susceptible to Deformation Under Pressure

Aluminum does have its limitations. While it is malleable, it needs to improve in strength and hardness compared to copper. Under high pressure, aluminum crush washers are susceptible to deformation and galling, compromising the seal’s integrity. Therefore, it’s essential to carefully assess the pressure requirements of your specific application before opting for aluminum crush washers.

Copper Crush Washers

Copper crush washers, similar to their aluminum counterparts, are small, flat rings used to create a tight seal between two surfaces under compression. The difference is they are made from copper, a metal known for its strength, conductivity, and corrosion resistance. But there’s more to copper crush washers. Let’s find out;

Strength and Conductivity

On the other hand, copper brings its advantages to the table. Copper crush washers are known for their exceptional strength and hardness, providing a reliable seal even under extreme pressure. Furthermore, copper exhibits excellent thermal and electrical conductivity, making it an ideal choice for applications that involve heat dissipation or electrical connections.

Resistance to Corrosion

Thanks to their copper composition, copper crush washers exhibit remarkable resistance against corrosion. This exceptional attribute ensures that the washers can withstand exposure to various elements, including saltwater, road salts, and other corrosive substances.

Plus, copper’s natural resistance to oxidation protects the washers from rusting. These qualities make copper crush washers an ideal choice, particularly for vehicles subjected to harsh weather conditions where durability and long-lasting performance are paramount.

Heavy Weight

Copper crush washers carry a substantial weight compared to alternatives like aluminum or nylon washers. When implemented in a car’s suspension system and other components, the additional weight of copper crush washers can contribute to heightened strain and increased damage.

It is crucial to carefully consider the implications of using copper crush washers, particularly in applications where weight plays a significant role.

Comparison between Aluminum and Copper Crush Washers

When comparing aluminum vs. copper crush washers, it’s crucial to consider several factors to make an informed decision.

Firstly, sealing effectiveness and durability play a significant role. While both materials can create reliable seals, copper’s superior strength and hardness provide an added advantage, especially in high-pressure applications.

Application-specific considerations are equally important. Assessing compatibility with different fluids and temperatures and the impact of pressure and vibration will help determine the ideal material. Additionally, cost and availability are essential factors to consider, as aluminum crush washers are often more cost-effective and readily available compared to copper crush washers.

Important Read: King Bearings vs Clevite Bearings: A Comprehensive Comparison

Comparatively, aluminum crush washers tend to be pricier than copper washers. However, the versatility of aluminum as a material allows it to be employed in a wide array of applications, ultimately rendering it a more cost-effective choice in the long term. Despite the initial higher cost, the value and adaptability of aluminum make it a wise investment that can deliver substantial benefits over time.

Both copper vs aluminum crush washers have unique advantages and drawbacks. Aluminum, known for its lightweight, offers corrosion resistance and non-magnetic properties. Copper exhibits exceptional strength and boasts excellent thermal and electrical conductivity. It’s essential to consider these characteristics when choosing between the two materials for specific applications.

Conclusion

Both materials have unique qualities and limitations in the aluminum vs. copper crush washer showdown. Aluminum offers lightweight and corrosion-resistant properties, making it a cost-effective choice for many applications. On the other hand, copper brings strength, hardness, and excellent conductivity to the table, albeit at a higher cost. Ultimately, your choice of crush washer material should align with your application’s specific requirements and considerations.