Do you have a high-performance vehicle, tow heavy loads, or use your car for heavy-duty purposes? Subjecting your vehicle to heavy loads or operating your car’s engine at maximum speed for extended durations can make the inclusion of an oil cooler highly advantageous.

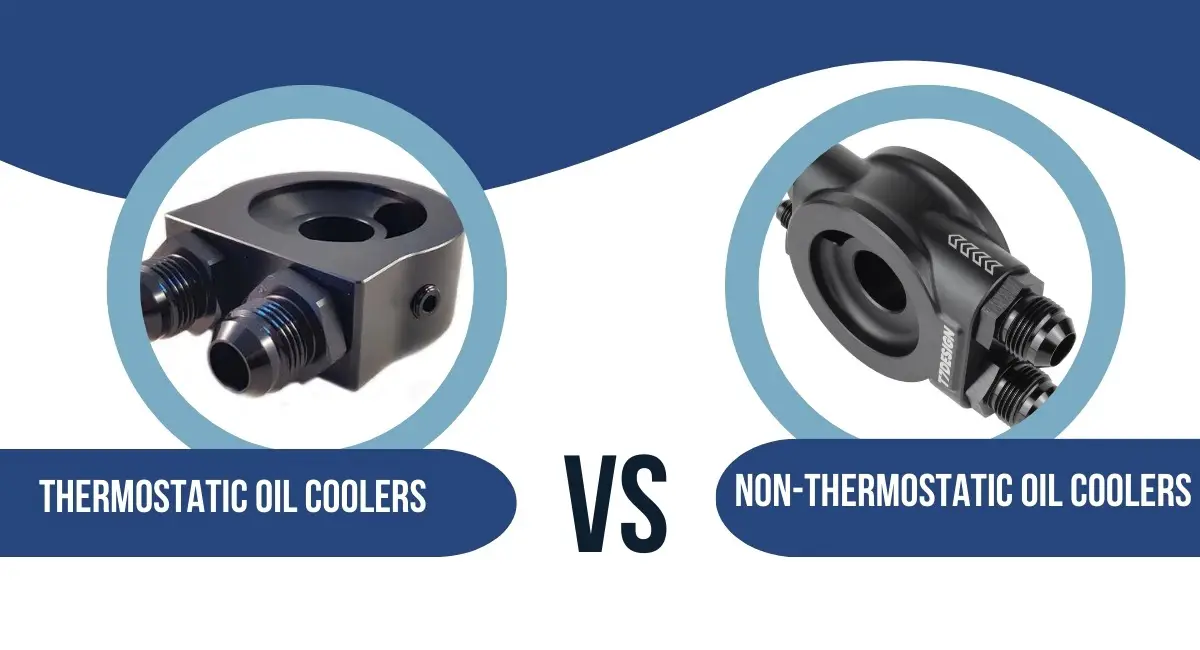

So, you need a thermostatic or non-thermostatic oil cooler to ensure the engines’ longevity and efficient performance. Thermostatic oil coolers feature a thermostat that controls oil flow based on temperature, allowing the engine to warm up quickly before cooling is initiated. In contrast, non-thermostatic oil coolers continuously cool the oil regardless of its temperature, providing consistent cooling without temperature-based regulation.

This article explores thermostatic versus non-thermostatic oil coolers, presenting a detailed exploration to illuminate their functionality, benefits, drawbacks, and ideal usage scenarios.

What are Oil Coolers

Oil coolers are critical components in maintaining an engine’s longevity and performance. They function similarly to radiators but are designed to cool the engine oil. By regulating the oil’s temperature, oil coolers help preserve the oil’s viscosity, ensuring it provides optimal lubrication and protection against wear under various operating conditions.

Importance of Oil Coolers

Oil coolers are essential for preventing overheating and maintaining engine efficiency. It is particularly true in high-performance, heavy-duty, or turbocharged engines that generate excessive heat. They contribute to:

- Prolonging engine life by reducing wear and tear.

- Extended oil life as it maintains oil viscosity for optimal lubrication.

- Enhancing overall vehicle performance by preventing power loss due to overheated oil.

Types of Oil Coolers

There are various ways of categorizing oil coolants. While it might get confusing, I’ll help you through. So, first, let’s explore the different types of engine coolants used in cars. These fluids are crucial in maintaining the engine’s temperature and preventing overheating. Here are the main types:

1. Inorganic Additive Technology (IAT)

Recognizable by its green color, IAT coolant is common in older vehicles. However, it’s less efficient and not frequently employed in modern cars.

2. Organic Acid Technology (OAT)

OAT coolant comes in various colors, such as orange, yellow, red, or purple. It is common in many modern vehicles due to its improved performance and compatibility with modern engine materials.

3. Hybrid Organic Acid Technology (HOAT)

HOAT is a blend of IAT and OAT technologies. It is often colored yellow or turquoise and balances the two other types.

Now, let’s move on to a different category. Regarding the various engine coolants and how the oil gets cooled, I have categorized them into thermostatic and non-thermostatic oil coolants.

Thermostatic Oil Coolers

Thermostatic oil coolers represent a sophisticated approach to managing engine oil temperature. These devices incorporate a thermostat that dictates when the oil cools based on its current temperature. This functionality allows the oil to reach optimal operating temperatures more rapidly and maintains it within this range, even under varying driving conditions.

How They Operate

The thermostat in a thermostatic oil cooler remains closed at lower temperatures, bypassing the cooler and allowing the oil to warm up quickly upon engine startup. Once the oil reaches a predetermined temperature—typically around 180°F (82°C)—the thermostat opens, allowing oil to flow through the cooler. This adaptive approach ensures that the oil is not over-cooled in cooler weather or during short trips, which can maintain fuel efficiency and engine performance.

Benefits

- Optimal Temperature Regulation: Thermostatic oil coolers provide optimal lubrication and reduced engine wear. This is possible by ensuring the oil rapidly reaches and maintains the ideal temperature.

- Improved Fuel Efficiency: By avoiding over-cooling, these coolers help maintain fuel efficiency, as the engine operates more efficiently at its designed temperature range.

- Enhanced Engine Performance: With better temperature control, engines can perform at their peak for extended periods, especially under high stress or in hot climates.

Drawbacks

- Cost and Complexity: Thermostatic oil coolers are generally more expensive and complex than their non-thermostatic counterparts, potentially increasing maintenance costs and complexity.

- Temperature Sensitivity: If the thermostat fails, it can lead to improper cooling, causing the engine to run too hot or too cold, which might damage the engine or reduce efficiency.

Non-Thermostatic Oil Coolers

In contrast, non-thermostatic oil coolers offer a more straightforward approach to oil cooling. These systems cool the oil regardless of temperature, constantly flowing through the cooler whenever the engine runs.

Functionality

Without a thermostat, non-thermostatic oil coolers continuously circulate oil through the cooler, relying on the ambient air or coolant temperature to regulate the oil temperature. This continuous cooling can be advantageous in consistently hot environments or under extreme driving conditions where overheating is a significant concern.

Benefits

- Simplicity and Cost-Effectiveness: With fewer moving parts and a more straightforward design, non-thermostatic coolers are generally less expensive and easier to maintain.

- Consistent Cooling: For vehicles operated in consistently high-temperature conditions or those that endure prolonged periods of high performance, the constant cooling can prevent oil from reaching excessively high temperatures.

Drawbacks

- Risk of Overcooling: In cooler climates or during short trips, non-thermostatic coolers can reduce oil temperature too much, potentially leading to increased wear and reduced efficiency.

- Lack of Temperature Control: With the ability to regulate flow based on temperature, these systems can adapt to changing driving conditions, leading to suboptimal performance in varying climates.

Factors to Consider When Choosing Between Thermostatic and Non-Thermostatic Oil Coolants

When choosing between a thermostatic and a non-thermostatic oil cooler, you should remember the following aspects:

- Driving Conditions: For those in cooler climates or who make many short trips, a thermostatic cooler’s ability to reach and maintain optimal temperatures quickly can be a significant advantage.

- Vehicle Use: High-performance or heavy-duty vehicles operating in hot climates or under extreme conditions may benefit more from the consistent cooling provided by non-thermostatic systems.

- Cost and Maintenance: Budget constraints and a preference for simplicity may lead some to favor the non-thermostatic option despite the potential drawbacks in temperature regulation.

- Personal Preferences and Priorities: Some drivers may prefer the efficiency and adaptability of a thermostatic cooler, while others might prioritize the simplicity and reliability of a non-thermostatic cooler. Also, consider how much you value the added engine protection from more precise temperature control, especially in extreme driving conditions.

- Engine Type and Design: Turbocharged and high-performance engines typically generate more heat, and a thermostatic oil cooler can help manage the temperature more efficiently by ensuring the oil is not overcooled in colder conditions. For regular use where engine temperatures are less extreme, a non-thermostatic oil cooler offers benefits in terms of longevity and performance, depending on other factors like climate and vehicle usage.

A Comparison of Thermostatic and Non-Thermostatic Oil Coolers

Here’s an easy way to make oil coolant system selection more straightforward. The table below will answer most of your concerns and help you settle for the best.

| Feature | Thermostatic Oil Coolants | Non-thermostatic Oil Coolants |

|---|---|---|

| Temperature Regulation | Incorporate a thermostat to regulate oil flow based on temperature, allowing the engine to warm up quickly before cooling is initiated. | Cool the oil continuously without temperature-based regulation, which can be beneficial in consistently high-temperature environments. |

| Operational Efficiency | They are more efficient in varied climates as they ensure the oil reaches optimal operating temperatures more rapidly and maintain it. | They are potentially less efficient in cooler climates or during short trips, as they might overcool the oil, affecting engine performance. |

| Cost and Complexity | Generally, it is more expensive and complex due to the inclusion of a thermostat mechanism. | They are simpler and often less expensive due to their straightforward cooling approach without temperature control. |

| Application Suitability | It is ideal for vehicles used in a wide range of operating conditions, especially where temperature fluctuations are typical. | Better suited for vehicles operating in consistently high-temperature conditions or with a desire for continuous cooling. |

| Maintenance and Reliability | Due to the complexity of the thermostat mechanism, it may require more maintenance, but it offers enhanced protection by preventing overheating and overcooling. | Due to its more straightforward design, it typically requires less maintenance, but the lack of temperature control could lead to issues in varying climates. |

This comparison highlights the operational differences and suitability of thermostatic versus non-thermostatic oil coolers, helping vehicle owners and mechanics make informed decisions based on their specific needs and operating conditions.

What is the Best Choice For You?

Consider how you use your vehicle, the typical driving conditions, and what you prioritize—whether it’s the adaptability and efficiency of a thermostatic cooler or the simplicity and consistent cooling of a non-thermostatic cooler.

It might also be helpful to consult with a mechanic or a performance specialist familiar with your vehicle type and use case. They can offer insights into which cooler would best suit your needs based on their experience. Besides, when making your choice, factor in the initial cost and potential savings in fuel efficiency, maintenance, and engine longevity.

Now that you have more insight into the two coolants—thermostatic and non-thermostatic—you can choose. I advise that the “best” choice depends on carefully considering your specific needs, driving habits, and the conditions under which your vehicle operates. There isn’t a one-size-fits-all answer, as each type of oil cooler offers distinct advantages tailored to different scenarios.

Conclusion

Both thermostatic and non-thermostatic oil coolers offer distinct advantages and challenges. You should choose between the two, considering the vehicle’s operating conditions, the typical environment for use, and the owner’s priorities regarding performance, fuel efficiency, and maintenance. By understanding these cooling systems’ fundamental differences and applications, drivers can make informed decisions that enhance their vehicle’s longevity and performance, ensuring optimal operation across various conditions.